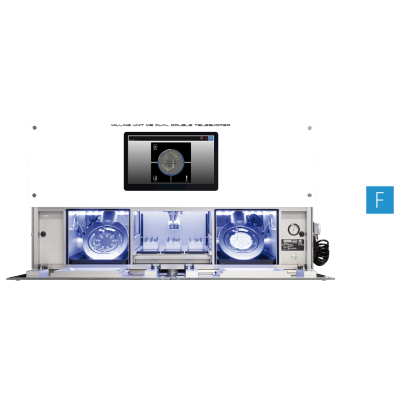

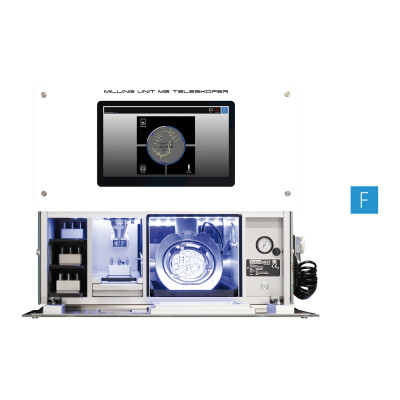

M6 Teleskoper Blank Changer Zirkonzahn

The M6 Teleskoper Blank Changer is an 'independent' milling machine with an integrated computerized control system. It features a removable block magazine capable of holding up to 16 material blocks, with an upgrade option to 80 blocks. Thanks to the Teleskoper M6 orbit (? 125 mm), it can automatically clamp and mill material blocks with diameters of ? 95 mm, ? 98 mm, ? 106 mm, and ? 125 mm. The machine includes a fully automatic block changer function, with real-time control and collision detection for safe and autonomous block exchanges between the block magazine and the orbit. The high-performance spindle provides a maximum torque of 200 Ncm and speeds from 6,000 to 50,000 rpm, with a peak power of 2.5 kW. This machine is capable of milling all common dental materials, both wet and dry, and offers effective cleaning with an ionizer and an automatic cleaning kit.Technical FeaturesIndependent milling machine with integrated computerized control systemTeleskoper M6 orbit (? 125 mm) for blocks of ? 95 / 98 / 106 / 125 mm (includes 1 Blank Holder Teleskoper Ø95 and 5 Blank Holder Soft Ø95)Fully automatic block changer function with real-time control and collision management for safe and autonomous block exchanges between the block magazine and the orbitRemovable block magazine, holds up to 16 blocks, upgradeable to 80 blocksIntegrated PC with 15' touchscreen for direct control of milling and calibration processesHigh-performance spindle with Permanent Magnet Synchronous Motor (PMSM), speeds of 6,000 to 50,000 rpm, peak power of 2.5 kWWet and dry milling of zirconia, resin, wax, pre-sintered metal, cobalt-chrome alloys, Raw-Abutments®, vitrocéramique, compositeSeparate tool holder chamber from the milling chamber with automatic tool change function (60 positions, 2 magazines of 30 positions each)QR code reader for intelligent insertion and verification of blocks in the magazineIntegrated ionizer for cleaner milling and reduced cleaning timesEasy maintenance with a new pivot door for quick access to the machineAutomatic cleaning and drying function with Cleaning Kit for manual cleaningTechnical DataWeight: 220 kg (Milling Machine 180 kg + Block Magazine 40 kg)Dimensions (L x H x D): 109 cm (+14 cm Cleaning Kit) x 69 cm x 62 cm (with suction connection)Housing: Tempered security glass ISO 12150Power: 2000 WPower Supply: 100 – 240 V~; 50 – 60 HzMilling Axes (Milling Machine): 5+1 axesMilling Axes (Blank Changer): 2+2 axesTool Changer: Automatic, 60 positionsNumber of Tools: 60 (2 magazines of 30 positions each)Milling Spindle: Performance Spindle with Permanent Magnet Synchronous Motor (PMSM, 6,000 – 40,000 rpm)Milling Spindle Power: Max. 2.5 kWMilling Spindle Torque: Constant 20 Ncm – Max. 200 NcmBlock Magazine: 16 or 80 material blocks (upgradeable)Block Management: Automated block management with optical recognitionMaterial Blocks: ? 95 mm, ? 98 mm, ? 106 mm, ? 125 mmMilling Angle Axis A/B: ± 30°Tool/Clamping Diameter: ? 6 mmTool Length: Up to 60 mmMeasurement Accuracy: ± 0.001 mm (1 ?)Tool Damage Detection: AutomaticCompressed Air: 6.5-9 bar input, 160 l/min at 6.5 bar, max. 400 l/min (chamber cleaning)Motors: Brushless with encoder (double encoder on the X-axis)Noise Level: < 60 dBLinear Axis Resolution: ± 0.001 mm (1 ?)Rotational Axis Resolution: ± 0.00045° = ± 0.00000785 radTool Management: AutomaticExternal Suction: Integrated output power up to 2000 W, relay for external devices